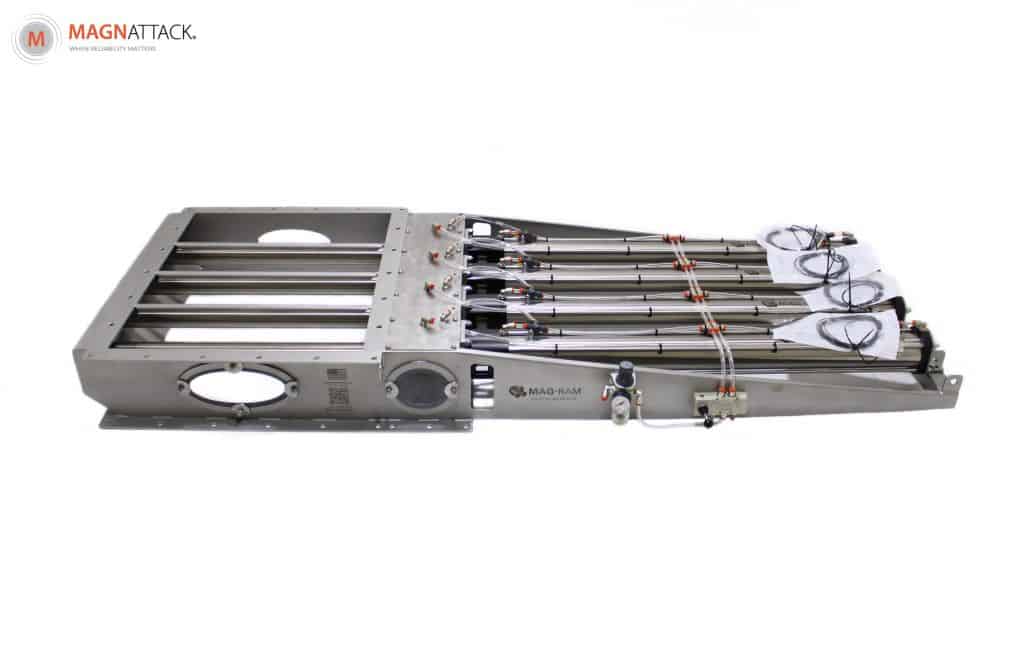

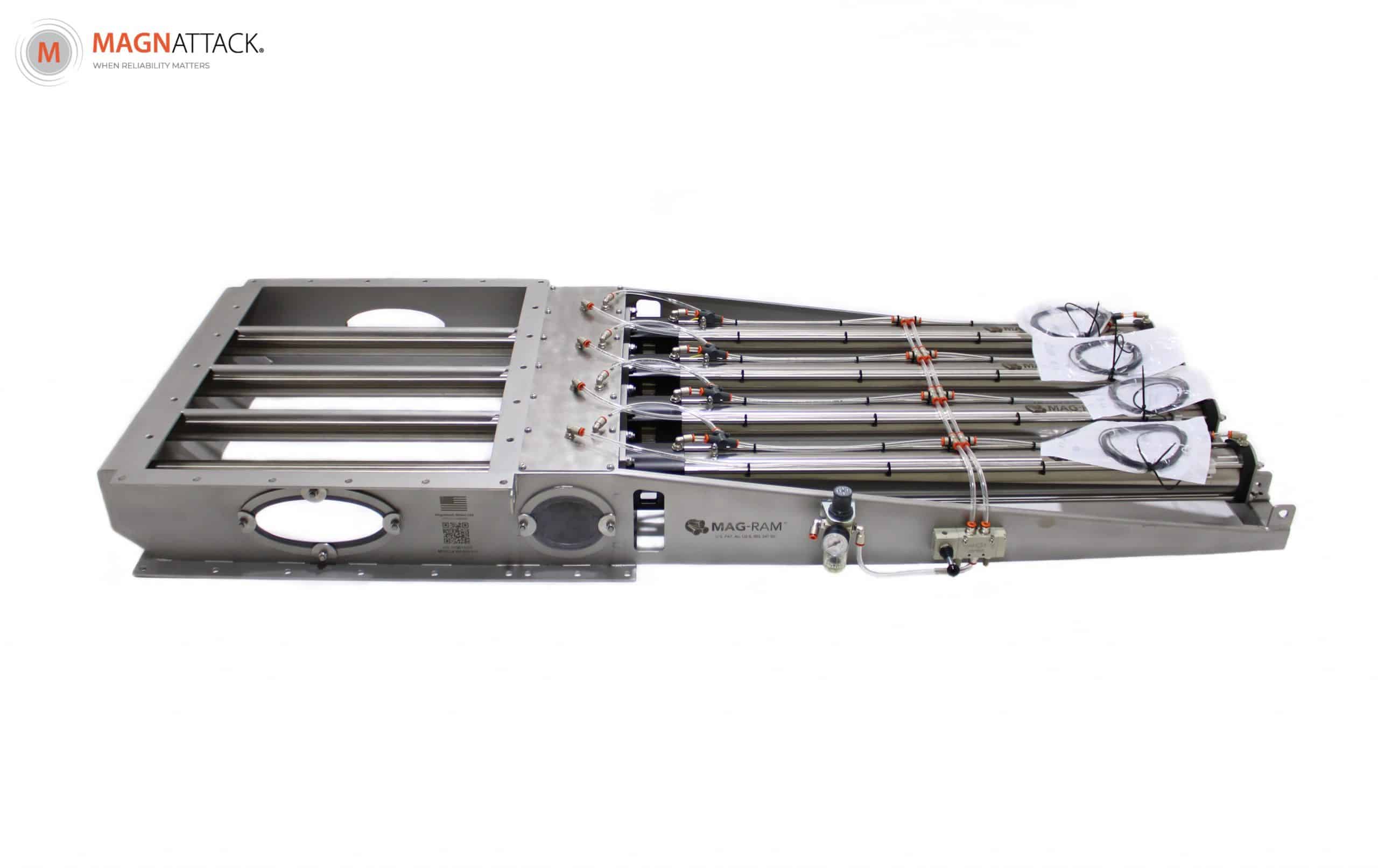

This is a 2 year case-study conducted by Mountaire, a respected USA meat rendering company, after installing the RE80® Mag-Ram® Automatic Self-Cleaning Magnetic Separator for product security in their finished rendered protein bulk-filling outloading.

This demonstrated that Mountaire were able to save time and money whilst also enhancing product security and increasing food safety.

Exploring Their Options

Mountaire, like most meat renderers, already had magnetic separators installed in their meat and bone meal process, however, it was becoming apparent that they needed to find a more effective method.

The aim of the project was to produce a higher quality product and increase customer confidence.

Although they could have simply installed additional magnets to provide another level of protection, it was necessary to determine whether this would be more effective or whether they should replace existing magnets with completely new systems.

Duane Purvis was involved in ensuring that the foreign object metal fragment controls were efficient and fit for purpose for harsh rendering applications.

The Main Issues

Magnets were difficult to clean – operators struggling to clean magnets can be a safety issue and, in some cases, can lead to magnets being returned to the product stream partially contaminated.

Dusty and abrasive product – moisture and dust can cause a solidified residue build-up on the magnets, impeding coverage and leading to magnets jamming.

Blockages – plugging chutes up with product meant production capacity was restricted, leading to loss of production and some downtime.

Product Wastage – some self-cleaning magnets are prone to excess carry-over to the contaminant chute, leading to product wastage and difficulty quantifying the reject sample.

Mag-Ram® – The Solution

After evaluating several locations in the process, Mountaire strategically placed the Mag-Ram® under the Shaker in the finished product. The Mag-Ram® demonstrated that it would give them greater control over foreign metal, less product wastage, increased product quality and value, and lead to improved customer satisfaction. After the installation of the Mag-Ram®, Duane stated “they work that well, you don’t even have to think about it”.

The Mag-Ram® is engineered to withstand many difficult to flow ingredients whilst providing optimum protection against small magnetic contamination fragments. The features that are unique to the Mag-Ram®:

Built in wear equalization – Each time the magnet Ram retracts for cleaning the Ram returns in a different position due to the activation of a special equalization mechanism deep within the magnetic assembly. This patented feature not only helps provide maximum longevity through wear equalization on the magnet and moving parts and seals, but also helps dislodge the pyramid of product on the top of the Ram, which contributes to a leaner contamination sample.

Dura-Slik® surfacing treatment – Higher moisture levels, temperature, fat content and humidity can hinder the flow. The Magnattack® Dura-Slik® surfacing treatment has anti-stick properties which minimize residue build-up, in comparison to polished or mill SS finish. This also helps to reduce abrasion to the magnets.

Exhaust Air Clean – Any additional clean product that may still be seated on the magnets when they are retracted into the contamination chamber for cleaning will likely be directed away by a gentle calibrated air stream (whilst leaving the magnetic contaminants on the magnet). This helps to further minimize the total loss or wasted clean product.

Cleaning Programme – The frequency of the cleaning cycle can be adjusted for optimum timing, depending on the demand for each application, such as continual cleaning or coinciding with screw fed applications.

Since Mountaire implemented the latest Mag-Ram® separator systems, the improvements were quickly noticeable.

The Investment

The Mag-Ram® is not an asset that increases the output capacity of the plant, so it was important to look deeper into the justification to manage the metal contamination risks.

By overcoming issues presented by inefficient and inadequate magnetic separators, and providing enhanced foreign metal fragment control, the Mag-Ram® Self Cleaning Separator has proven to be a valuable and worthwhile addition to several rendering plants around the world.

The Mag-Ram® is widely patented in North America, Australia, New Zealand, and Europe.